Machining Center

VDF Series

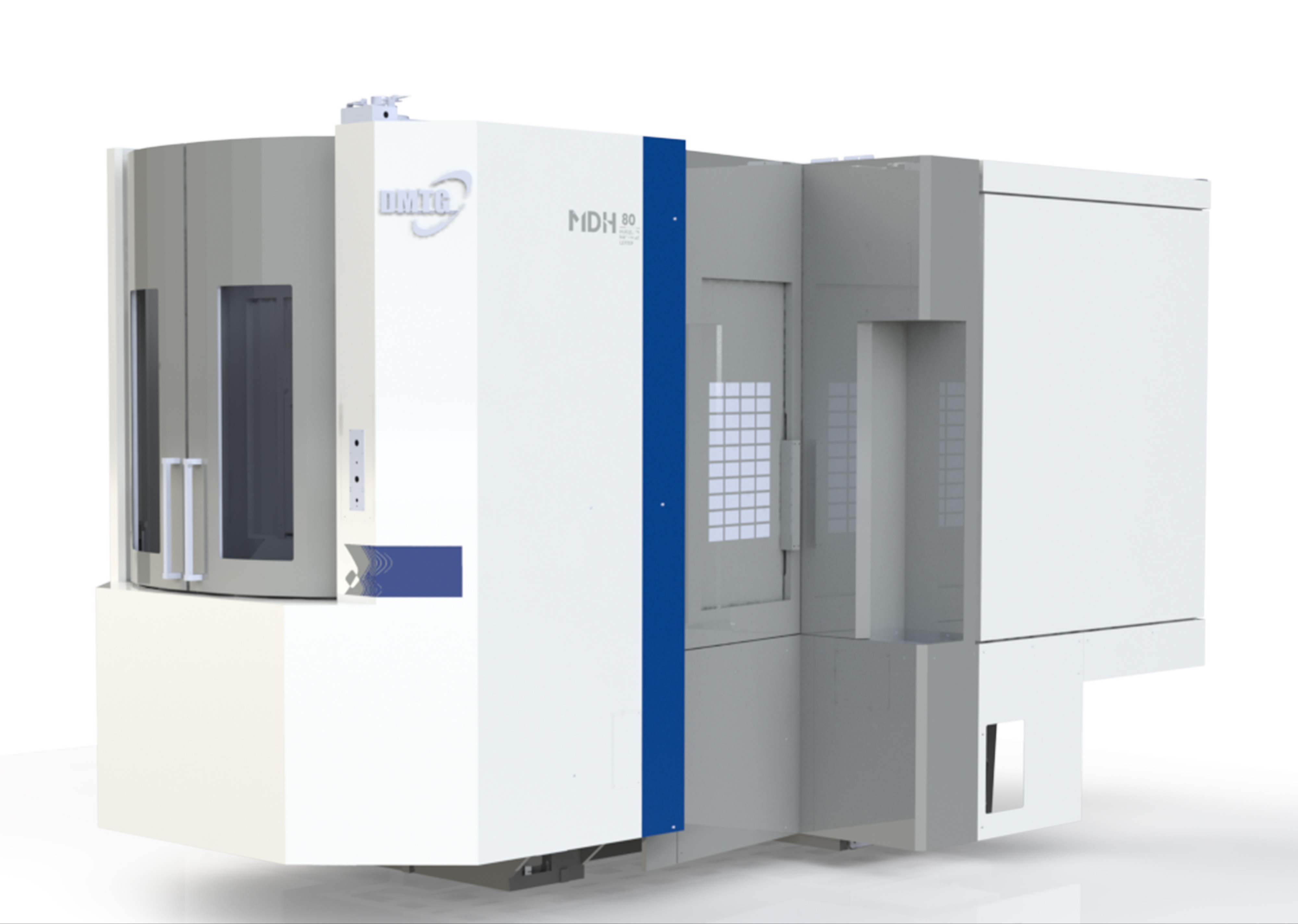

The VDF series vertical machining center is a new generation of rail-type vertical machining center developed and manufactured by our company. This machine tool is widely applicable in industries such as automotive, molds, mechanical manufacturing, and more, for the machining of box components, casing parts, disc-shaped parts, and complex-shaped parts. With a single setup, this machine can automatically complete multi-step processes including milling, boring, drilling, reaming, tapping, and thread milling on all four sides of the workpiece.

Application Fields:

The VDF series vertical machining center is a new generation of rail-type vertical machining center developed and manufactured by our company. This machine tool is widely applicable in industries such as automotive, molds, mechanical manufacturing, and more, for the machining of box components, casing parts, disc-shaped parts, and complex-shaped parts. With a single setup, this machine can automatically complete multi-step processes including milling, boring, drilling, reaming, tapping, and thread milling on all four sides of the workpiece.

Main Performance and Features:

1. Foundational components such as the machine base, column, spindle headstock, cross slide, and worktable are all made of high-strength cast iron with stable organization, ensuring quality.

2.High-speed and high-precision spindle:

①The spindle motor employs a high-torque toothed belt drive, preventing slippage and significantly reducing transmission noise and heat.

②Precision-grade angular contact bearings are used for the spindle.

③High-performance grease lubricates the spindle bearings, and an economical spindle head cooling system effectively controls spindle temperature rise.

④The spindle is balanced using the IRD dynamic balance correction device, directly correcting the spindle's dynamic balance. This prevents resonance during high-speed operation and ensures machining precision.

3. High-precision ball screw pairs: After pre-tensioning, the ball screw greatly increases transmission stiffness while eliminating the thermal deformation effects during rapid motion, ensuring positioning accuracy and repeatability.

4. Automatic tool changer system with pneumatic and electric control actions, free of pollution, easy to maintain, and offering quick and reliable tool exchanges.

5. The machine is equipped with a complete protective cover for aesthetics, safety, leak prevention, and environmental protection. The spiral-type automatic chip removal device is simple, environmentally friendly, and suitable for transporting both metal and non-metal chips.

6. Highly efficient automatic lubrication system with good lubrication properties and minimal oil wastage.

7. Ingenious oil-water separation equipment reduces the mixing of cutting fluid and oil, preventing deterioration of the cutting fluid and extending its lifespan.

8. The wiring inside the electrical box conforms to safety standards, ensuring the control system operates without external interference. The electrical box is equipped with a heat exchanger to effectively control the temperature within, ensuring stable long-term operation of the control system.

9. High-precision lead compensation: Each transmission shaft employs high-precision laser measurement compensation, enhancing the accuracy of each axis's positioning and making it more suitable for machining high-precision parts.

| Specification | Unit | VDF1500 |

| Worktable size(Lx W) | mm | 1700X800 |

| Max. load | kg | 2500 |

| T-slots(numbers*width* centre distance) | mm | 6X18X125 |

| X/Y/Z axis travel | mm | 1560/830/790 |

| X/Y/Z axis guide way type | Box way (Y -4) | |

| Distance from spindle center to column | mm | 850 |

| Distance from spindle nose to table | mm | 186 ~ 976 |

| Spindle motor power | kw | 15/18.5 |

| Max. spindle speed | r/min | 6000 |

| Spindle taper | No.50(7/24) | |

| Rapid traverse of X/Y/Z axis | m/min | 15/15/12 |

| Max. cutting feed rate | m/min | 6 |

| Tool magazine capacity | 24T/Arm | |

| Tool shank type | BT50 | |

| Max. tool weight | kg | 15 |

| Max. tool diameter (w/o adjacent tools) | mm | 24T:Φ125/250 |

| Tool change time (T-T) | s | 3.5 |

| X/Y/Z axis positioning accuracy | mm | 0.019/0.008/0.008 |

| X/Y/Z axis repeatability accuracy | mm | 0.008/0.005/0.005 |

| CNC controller | FANUC 0i-MF (1) PIUS,SIEMENS 828D | |

| Machine dimensions(L×W×H) | mm | 4580×3250×3120 |

| Machine weight | kg | 14000 |

| Specification | Unit | VDF1800 |

| Worktable size(Lx W) | mm | 2000X800 |

| Max. load | kg | 2500 |

| T-slots(numbers*width* centre distance) | mm | 6X18X125 |

| X/Y/Z axis travel | mm | 1880/830/790 |

| X/Y/Z axis guide way type | Box way (Y - 4) | |

| Distance from spindle center to column | mm | 850 |

| Distance from spindle nose to table | mm | 166 ~ 956 |

| Spindle motor power | kw | 15/18.5 |

| Max. spindle speed | r/min | 6000 |

| Spindle taper | No.50(7/24) | |

| Rapid traverse of X/Y/Z axis | m/min | 15/15/12 |

| Max. cutting feed rate | m/min | 6 |

| Tool magazine capacity | 24T/Arm | |

| Tool shank type | BT50 | |

| Max. tool weight | kg | 15 |

| Max. tool diameter (w/o adjacent tools) | mm | 24T:Φ125/250 |

| Tool change time (T-T) | s | 3.5 |

| X/Y/Z axis positioning accuracy | mm | 0.019/0.008/0.008 |

| X/Y/Z axis repeatability accuracy | mm | 0.008/0.005/0.005 |

| CNC controller | FANUC 0i-MF (1) PIUS,SIEMENS 828D | |

| Machine dimensions(L×W×H) | mm | 5200×3250×3120 |

| Machine weight | kg | 14500 |

Sales network