CNC Lathe

DT/DT-H Series

The DT series slant bed CNC lathes are widely applicable for the machining of shaft components and disc-type parts in industries such as automotive, mold-making, bearings, oil, and coal machinery manufacturing. Parts can be automatically processed through multiple operations like turning and boring after a single clamping.

Application:

Fields The DT series slant bed CNC lathes are extensively utilized for the machining of shaft components and disc-type parts in industries such as automotive, mold-making, bearings, oil, and coal machinery manufacturing. Parts can be automatically processed through multiple operations like turning and boring after a single clamping.

Machine Features:

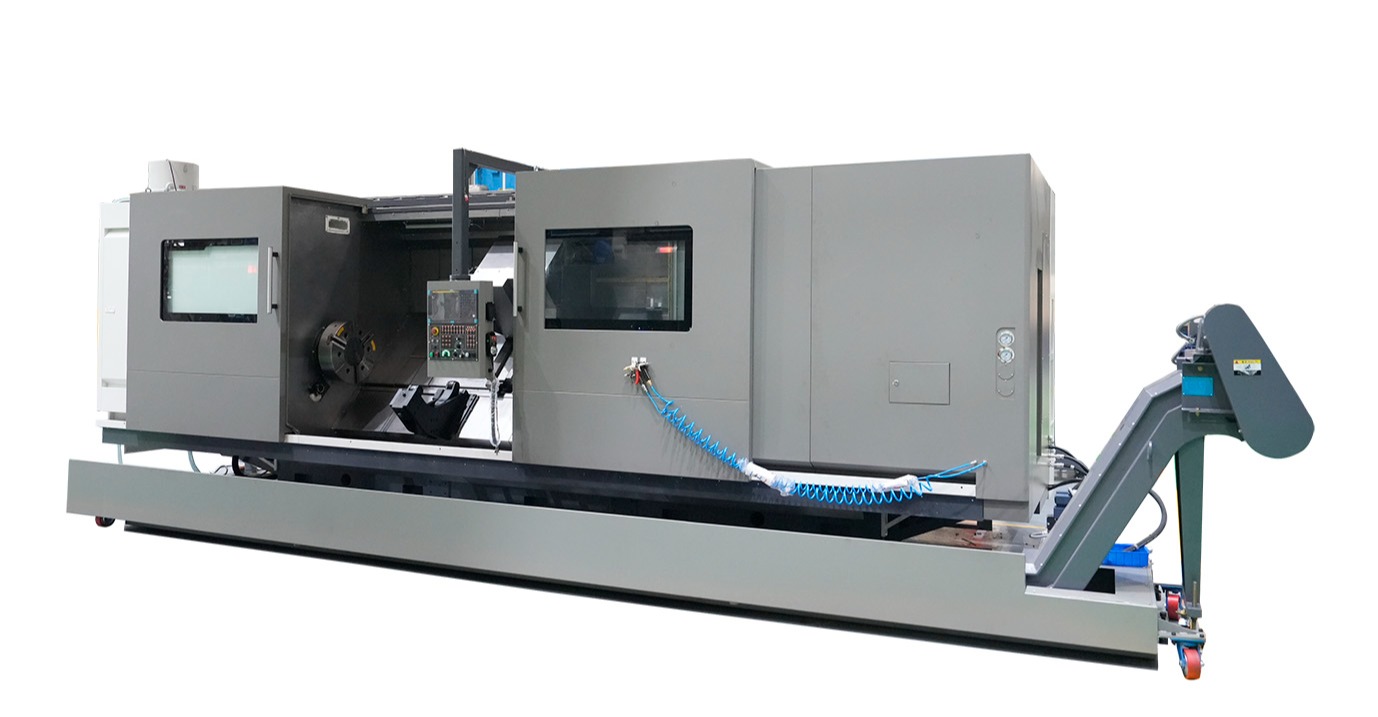

1. Configurable rear chip conveyor, particularly suitable for integration into production lines.

2. Spacious working area capable of accommodating special fixtures, automatic loading and unloading, and other specialized attachments, making it especially suitable for integration into production lines.

3. Equipped with Fanuc 0i-TF(5) system featuring USB ports and a 10.4" color LCD display.

4. High rigidity structural design: The bed is cast as a whole, with the bed guide rail inclined at 40°, offering a large bearing cross-section, excellent rigidity, and vibration absorption. This ensures high-precision cutting.

5. High efficiency, low noise design: The main drive system of the machine employs AC servo motor drive, coupled with high-efficiency parallel V-belt transmission for direct spindle drive. This design avoids noise issues caused by gearbox transmission chains.

6. High-speed, high-rigidity spindle: The front and rear ends of the spindle feature NSK precision high-speed spindle bearings with appropriate preloading force. Coupled with an ideal span support and a box-type spindle housing, the spindle exhibits high rigidity and high-speed operation capability.

7. Highly reliable tool turret: Equipped with a high-rigidity hydraulic turret, it offers high reliability and repeatable positioning accuracy.

8. Precise and fast longitudinal and cross-axis drives: The machine utilizes ball screws and linear roller guides, offering high transmission efficiency and good accuracy retention. This ensures rapid and stable movement of the tool turret, with high positioning accuracy.

9. High-precision hydraulic tailstock: Provides accurate centering assurance for turning operations.

10. Automatic centralized lubrication system: Ensures continuous and effective lubrication of the guide rails and ball screws.

11. Complete enclosure for protection: The machine is fully enclosed to prevent coolant leakage. The industrial-styled design, layout with left sliding door and right control panel, offers an aesthetically pleasing appearance that emphasizes human-machine functionality, providing a safe and comfortable working environment for operators.

12. Chip and cooling system: An independent chip and cooling system is equipped with a high-flow cooling pump and a chain-type chip conveyor, providing forced cooling and automatic chip disposal for turning operations.

| Specification | Unit | DT-30 | DT-30H | ||

| Max. swing diameter over bed | mm | Φ480 | |||

| Max. turning diameter (Shaft/Disc) | mm | Φ280/Φ300 | Φ280/Φ300 | ||

| Max. turning length | mm | 300 | 300 | ||

| Guideway type | Linear guideway | ||||

| Type of spindle nose | A2-5 | Opt:A2-6 | A2-5 | Opt:A2-6 | |

| Chuck size | inch | 6 | 8 | 6 | 8 |

| Spindle speed range | rpm | 5000 | 4500 | 5000 | 4500 |

| Spindle bore | mm | Φ63 | Φ63 | Φ63 | Φ63 |

| Max.bar capacity (Equipped with through-hole hydraulic chuck) | mm | Φ45 | Φ47 | Φ45 | Φ47 |

| Spindle motor power | KW | 7.5/11 | |||

| Max. travel of X axis | mm | 155 | 170 | ||

| Max. travel of Z (Y) axis | mm | 300/500 | 300 | ||

| Rapid traverse of X/Z(Y) axis | m/min | 30/30 | |||

| Turret type and tool numbers | Hydraulic 12-position turret |

Live tooling 12-position turret |

|||

| Tool shank size | mm | 25X25 | 20X20 | ||

| Indexing time(adjacent/farthest) | S | 0.35/1.6 | 0.31/0.76 | ||

| Diameter of tailstock quill | mm | Φ70 | |||

| Tailstock quill stroke | mm | 120 | |||

| X/Z(C、Y) axis positioning accuracy | mm | 0.005/0.005 | 0.005/0.005 C:44” | ||

| X/Z(C、Y) axis repeatability accuracy | mm | 0.003/0.003 | 0.003/0.003 C:18” | ||

| CNC Controller | FANUC 0i-TF (5) Plus, FANUC 0i-TF (1) PIUS, SIEMENS SINUMERIK 828D |

||||

| Machine dimensions(L×W×H) Without chip conveyor |

mm | 2360×1720×1835(300) | |||

| Machine weight | kg | 4000/4800 | |||

| Specification | Unit | DT-40 | DT-40H | ||

| Max. swing diameter over bed | mm | Φ580 | |||

| Max. turning diameter (Shaft/Disc) | mm | Φ360/Φ400 | Φ350/Φ350 | ||

| Max. turning length | mm | 585/1085 | 555/1055 | ||

| Guideway type | Linear guideway | ||||

| Type of spindle nose | A2-6 | Opt:A2-8 | A2-6 | Opt:A2-8 | |

| Chuck size | inch | 8 | 10 | 8 | 10 |

| Spindle speed range | rpm | 4000 | 3500 | 4000 | 3500 |

| Spindle bore | mm | Φ70 | Φ87 | Φ70 | Φ87 |

| Max.bar capacity (Equipped with through-hole hydraulic chuck) | mm | Φ51 | Φ73 | Φ51 | Φ73 |

| Spindle motor power | KW | 11/15 | |||

| Max. travel of X axis | mm | 215 | |||

| Max. travel of Z (Y) axis | mm | 600/1100 | 555/1055(ITALY) 445/945(CHINA) |

||

| Rapid traverse of X/Z(Y) axis | m/min | 30/30 | |||

| Turret type and tool numbers | Hydraulic 12-position turret |

Live tooling 12-position turret |

|||

| Tool shank size | mm | 25X25 | |||

| Indexing time(adjacent/farthest) | S | 0.35/1.6 | 0.49/0.96(ITALY) | ||

| Diameter of tailstock quill | mm | Φ85 | |||

| Tailstock quill stroke | mm | 140 | |||

| X/Z(C、Y) axis positioning accuracy | mm | 0.005/0.007、0.008 | 0.005/0.070、008(C:31") | ||

| X/Z(C、Y) axis repeatability accuracy | mm | 0.003/0.004、0.005 | 0.003/0.004、0.005(C:13") | ||

| CNC Controller | FANUC 0i-TF (5) Plus, FANUC 0i-TF (1) PIUS, SIEMENS SINUMERIK 828D |

||||

| Machine dimensions(L×W×H) Without chip conveyor |

mm | 2922×1900×2010(600) 3422×1900×2010(1000) |

|||

| Machine weight | kg | 5300/6300 | |||

| Specification | Unit | DT-50 | DT-50H | DT-50HS |

| Max. swing diameter over bed | mm | Φ680 | ||

| Max. turning diameter (Shaft/Disc) | mm | Φ460/Φ500 | Φ450/Φ450 | Φ440/Φ440 |

| Max. turning length | mm | 580/1080 | 555/1055(ITALY) 445/945(CHINA) |

440/940 |

| Guideway type | Linear guideway | |||

| Type of spindle nose | A2-8 | |||

| Chuck size | inch | 10 | ||

| Spindle speed range | rpm | 3500 | 3500 | 3500 4000 (sub-spindle) |

| Spindle bore | mm | Φ87 | ||

| Max.bar capacity (Equipped with through-hole hydraulic chuck) | mm | Φ73 | ||

| Spindle motor power | KW | 15/18.5 | 7.5/15(Low) 11/18.5(High) |

|

| Max. travel of X axis | mm | 265 | ||

| Max. travel of Z (Y) axis | mm | 600/1100 | 555/1055(ITALY) 445/945(CHINA) |

460/960 |

| Rapid traverse of X/Z(Y) axis | m/min | 30/30 | ||

| Turret type and tool numbers | Hydraulic 12-position turret |

Live tooling 12-position turret |

Live tooling 12-position turret |

|

| Tool shank size | mm | 25X25 | ||

| Indexing time(adjacent/farthest) | S | 0.35/1.6 | 0.49/0.96 (ITALY) |

0.49/0.96 (ITALY) |

| Diameter of tailstock quill | mm | Φ85 | Sub-spindle | |

| Tailstock quill stroke | mm | 140 | ||

| X/Z(C、Y) axis positioning accuracy | mm | 0.005/0.007、0.008 | 0.005/0.0070.008(C:31") | 0.005/0.007.0.008(C:31") |

| X/Z(C、Y) axis repeatability accuracy | mm | 0.003/0.004、0.005 | 0.003/0.004、0.005(C:13") | 0.003/0.004、0.005(C:13") |

| CNC Controller | FANUC 0i-TF (5) Plus, FANUC 0i-TF (1) PIUS, SIEMENS SINUMERIK 828D |

FANUC 0i-TF Plus(1) | ||

| Machine dimensions(L×W×H) Without chip conveyor |

mm | 2922×1900×2010(600) 3422×1900×2010(1000) |

3222×1900×2010(600) 3850×1900×2010(1000) |

|

| Machine weight | kg | 5500/6500 | 6500/6700 | |

Sales network