CNC Lathe

CKE Series

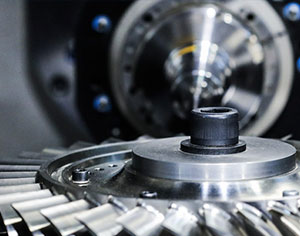

The CKE series CNC lathes are CNC horizontal bed lathes controlled in both longitudinal (Z-axis) and cross (X-axis) directions. They are capable of automatically performing cutting processes on various shaft and disc-type parts, including internal and external cylindrical surfaces, conical surfaces, circular arc surfaces, end faces, grooves, chamfers, etc. Moreover, they can also handle turning operations for metric straight threads, end face threads, imperial straight threads, and tapered threads. These lathes are suitable for the production of a variety of products in medium to small batches, excelling in the machining of complex and high-precision parts.

Machine Features:

1.The machine is designed using finite element analysis, which theoretically analyzes and calculates the overall layout and key structures of the machine. This results in high rigidity, minimal thermal deformation, low spindle temperature rise, low vibration, and the ability to withstand high cutting torque. These characteristics enable the machine to adapt to heavy-duty cutting and achieve an internationally advanced design concept.

2.Key purchased components of the machine, such as the CNC system and spindle bearings, are sourced from renowned domestic and international manufacturers, ensuring high reliability of the machine.

3.Advanced structural design combined with comprehensive process measures ensure the machine possesses high machining accuracy and long-term precision retention. The consistency of machined workpieces is excellent, achieving stable precision levels ranging from IT6 to IT7, with a surface roughness of up to Ra1.6μm.

4.Key parts of the machine, including the bed, headstock housing, saddle, and tailstock, undergo processing using advanced equipment. The utilization of top-notch processing equipment guarantees high precision of machine components, which is essential for ensuring various technical performances of the machine.

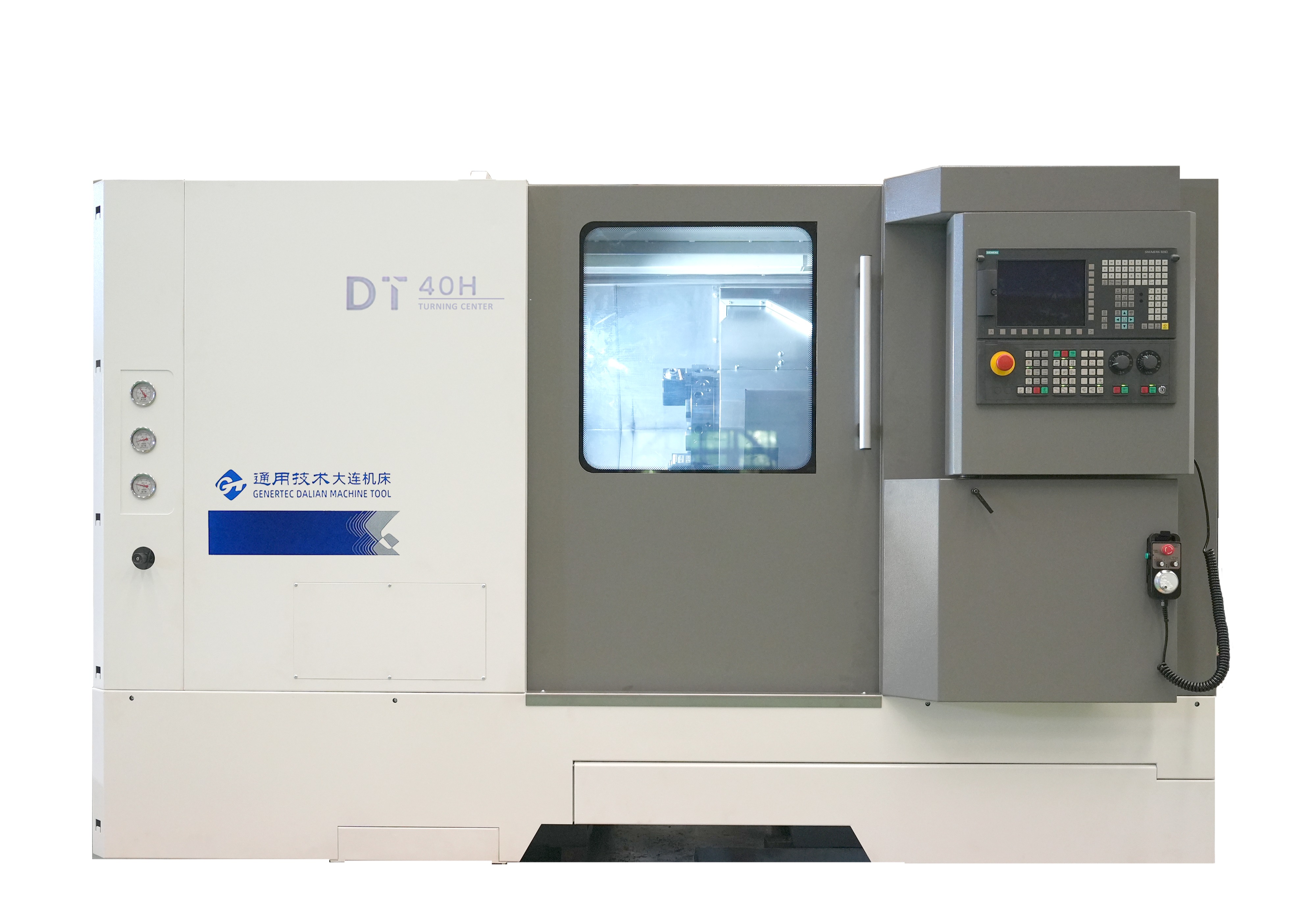

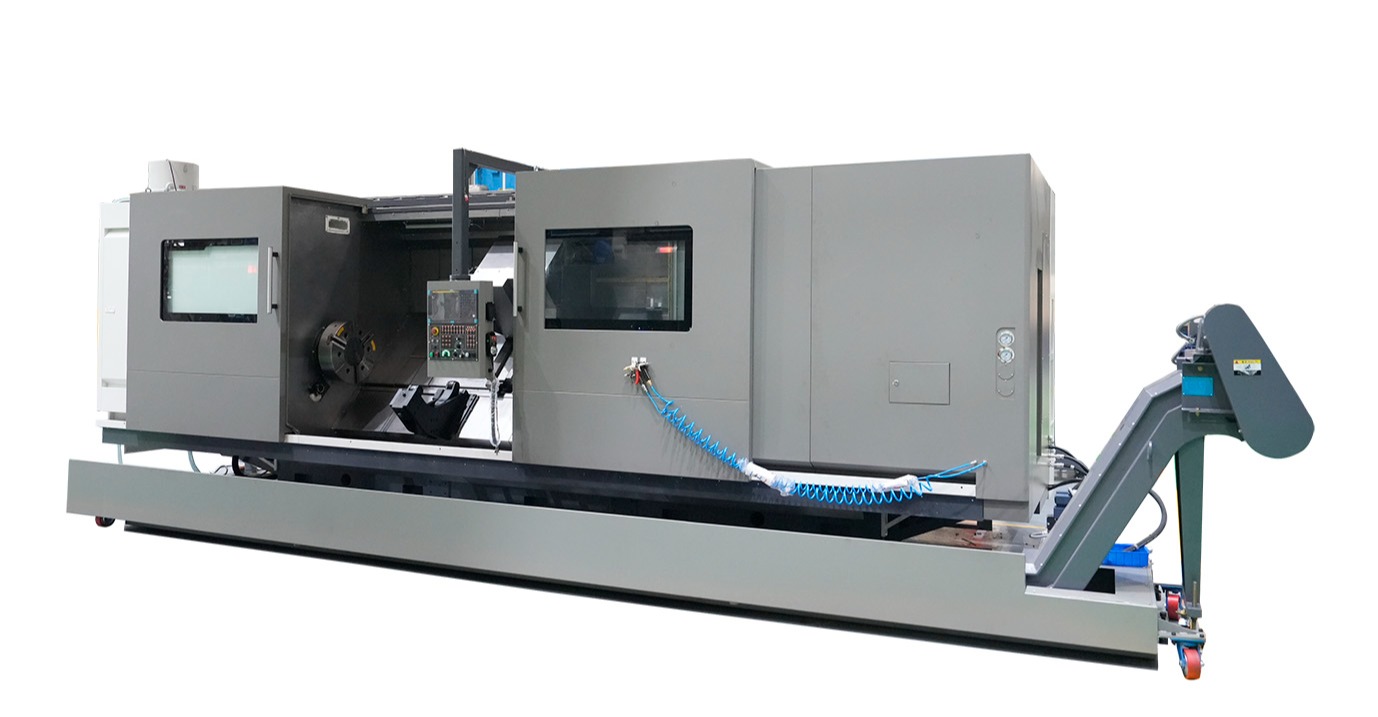

5.The machine adopts an integrated mechanical and electrical design, featuring a compact and rational layout that offers user-friendly and pleasant operation, as well as ease of maintenance.

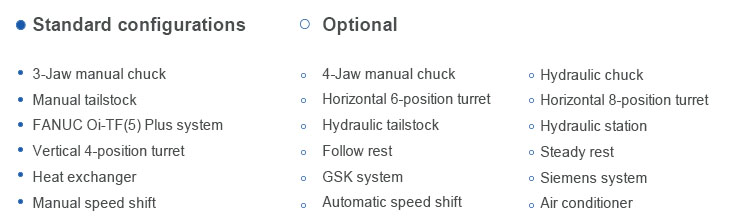

6.The machine follows a modular design approach, allowing for various configurations to be provided based on user requirements (e.g., different tool turrets, tailstocks, systems, etc.).

| Specification | Unit | CKE6150Z | CKE6150i | |

| Max. swing diameter over bed | mm | Φ500 | ||

| Max. swing diameter over cross slide | mm | Φ280 | ||

| Max. workpiece length | mm | 750/1000/1500/2000 | 750/1000 | |

| Max. cutting length | mm | 680/930/1430/1930 | 680/930 | |

| Max. turning length | Vertical 4-position |

mm | Φ500 | |

| Opt:Horizonta 6-position |

mm | Φ400 | ||

| Opt:Horizonta 8-position |

mm | Φ370 | ||

| Spindle center height | mm | 250 | ||

| Bed guideway width | mm | 400 | ||

| Spindle motor power | kW | 7.5/11 (Servo motor) |

11/15 (Servo motor) |

|

| Spindle type | r/min | Gear box | Belt driven | |

| Spindle bore | mm | Φ82 | ||

| Chuck size | mm | Φ250 | Φ254 | |

| Taper of spindle bore | Front end Φ90 1:20 |

Front end Φ100 1:20 |

||

| Type of spindle nose | D8 | A2-8 | ||

| Spindle speed ranges | r/min | *7~2200 3 range manual(auto) |

*30~3000 Single spindle |

|

| Tailstock quill diameter | mm | Φ75 | ||

| Tailstock quill travel | mm | 150 | ||

| Tailstock quill taper | MT 5 | |||

| Max. trave lof X-axis | mm | 280 | ||

| Max. travel of Z-axis | mm | 685/935/1435/1935 | 685/935 | |

| Rapid traverse of X/Z axis | m/min | 4/8 (750、1000、1500) 4/6 (2000) |

4/8 | |

| Tool shank size (Vertical 4-positon) | mm | 25X25 | 25X25 | |

| X/Z axis positioning accuracy | mm | 0.018/0.021(750) 0.024(1000)0.026(1500、2000) |

0.018/0.021(750)0.024(1000) | |

| X/Z axis repeatability accuracy | mm | 0.006/0.008(750)0.011(1000) 0.014(1500、2000) |

0.006/0.008(750) 0.011(1000) |

|

| Machine dimensions(L×W×H) | mm | 2580×1750×1620(750) 2830×1750×1620(1000) 3330×1750×1620(1500) 3830×1750×1620(2000) |

2580×1750×1620(750) 2830×1750×1620(1000) |

|

| Machine weight | kg | 2550(750)2600(1000) 2700(1500)2800(2000) |

2550(750) 2600(1000) |

|

| Specification | Unit | CKE6163Z | CKE6180Z | CKE61100Z | |

| Max. swing diameter over bed | mm | Φ630 | Φ800 | Φ1000 | |

| Max. swing diameter over cross slide | mm | Φ320 | Φ490 | Φ700 | |

| Max. workpiece length | mm | 1000/1500/2000/3000/4000/5000 | 1000/1500 | ||

| Max. cutting length | mm | 795/1245/1845/2745/3785/4745 (Vertical 4-position) 690/1140/2740/2640/3680/4640 (Horizontal 6-position) 700/1150/2750/2650/3690/4650 (Horizontal 8-position) |

795/ 1245 (Vertical 4-position) 690/1140 (Horizontal 6-position) 700 /1150 (Horizontal8-position) |

||

| Max. turning length | Vertical 4-position |

mm | Φ630 | Φ800 | Φ800 |

| Opt:Horizonta 6-position |

mm | Φ620 | Φ620 | Φ620 | |

| Opt:Horizonta 8-position |

mm | Φ620 | Φ620 | Φ620 | |

| Spindle center height | mm | 315 | 400 | 515 | |

| Bed guideway width | mm | 550 | 550 | 550 | |

| Spindle motor power | kW | 11 (inverter-driven motor) | |||

| Spindle type | r/min | Gear box | |||

| Spindle bore | mm | Φ100 | |||

| Chuck size | mm | Φ315 | Φ400 | Φ500 | |

| Taper of spindle bore | Front end Φ120 1:20 |

||||

| Type of spindle nose | C11 | ||||

| Spindle speed ranges | r/min | 10~1000 4 range manual(auto) | |||

| Tailstock quill diameter | mm | Φ100 | |||

| Tailstock quill travel | mm | 240 | |||

| Tailstock quill taper | MT 6 | ||||

| Max. trave lof X-axis | mm | 320 | 400 | 400 | |

| Max. travel of Z-axis | mm | 800/1250/1850/2750/3790/4750 | 800/1250 | ||

| Rapid traverse of X/Z axis | m/min | 4/7.5(1000、1500、2000)、 4/4(3000)、4/3.5(4000、 5000) |

|||

| Tool shank size (Vertical 4-positon) | mm | 32 X32(32 X25 Horizontal 8-position) | |||

| X/Z axis positioning accuracy | mm | 0.018/0.024(1000) 0.026(1500、2000) 0.030(3000、4000、5000) |

0.018/0.024(1000) 0.026(1500) |

||

| X/Z axis repeatability accuracy | mm | 0.006/0.011(1000) 0.014(1500、2000、3000、4000、5000) |

0.006/0.011(1000) 0.014(1500 |

||

| Machine dimensions(L×W×H) | mm | 3455×2020×1805(1000) 3905×2020×1805(1500) 4505×2020×1805(2000) 5405×2020×1805(3000) 6455×2020×1805(4000) 7535×2020×1805(5000) |

3455X2020X2000(1000) 3905X2020X2000(1500) |

||

| Machine weight | kg | 4800/5100/5600/ 5900/7100/8100 |

5300/5600/6100/ 6400/7600/8600 |

5600/6000 | |

Sales network